MicroVention Terumo - EIT Rotation Program

Engineer I - Manufacturing Engineering (June 2020 - March 2021)

Engineer I - Equipment Design Engineering (March 2021 - November 2021)

Engineer I - Business Analytics (November 2021 - March 2022)

About the EIT Rotation Program

During my time at MicroVention, I was part of the EIT Rotation Program. This program is designed to give new incoming engineers, typically out of university, the opportunity to explore different engineering and non engineering disciplines as an Engineer Level I. The program allows for three 8 month rotations in the following areas/departments (1):

• Manufacturing Engineering

• Receiving/Production Specification Analysis

• Equipment/Tool Design

• Marketing

• Regulatory Affairs

• Business Excellence

• Quality

Learn more about the EIT Rotation with the button below.

Image Credit (2)

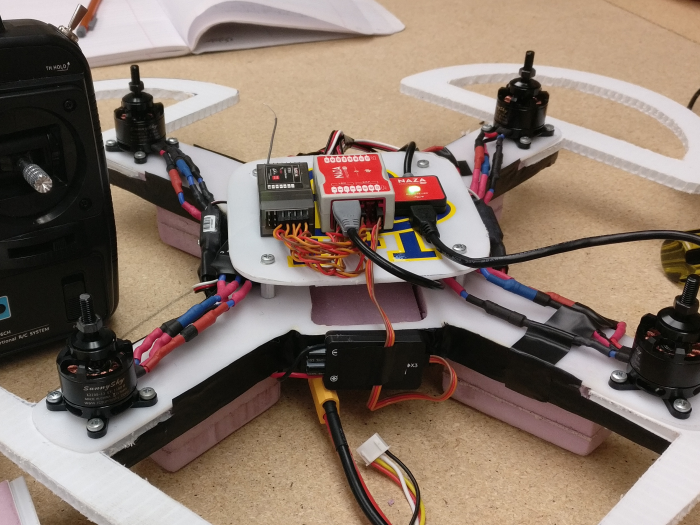

My First Role: Engineer I - Manufacturing Engineering

June 2020 - March 2021

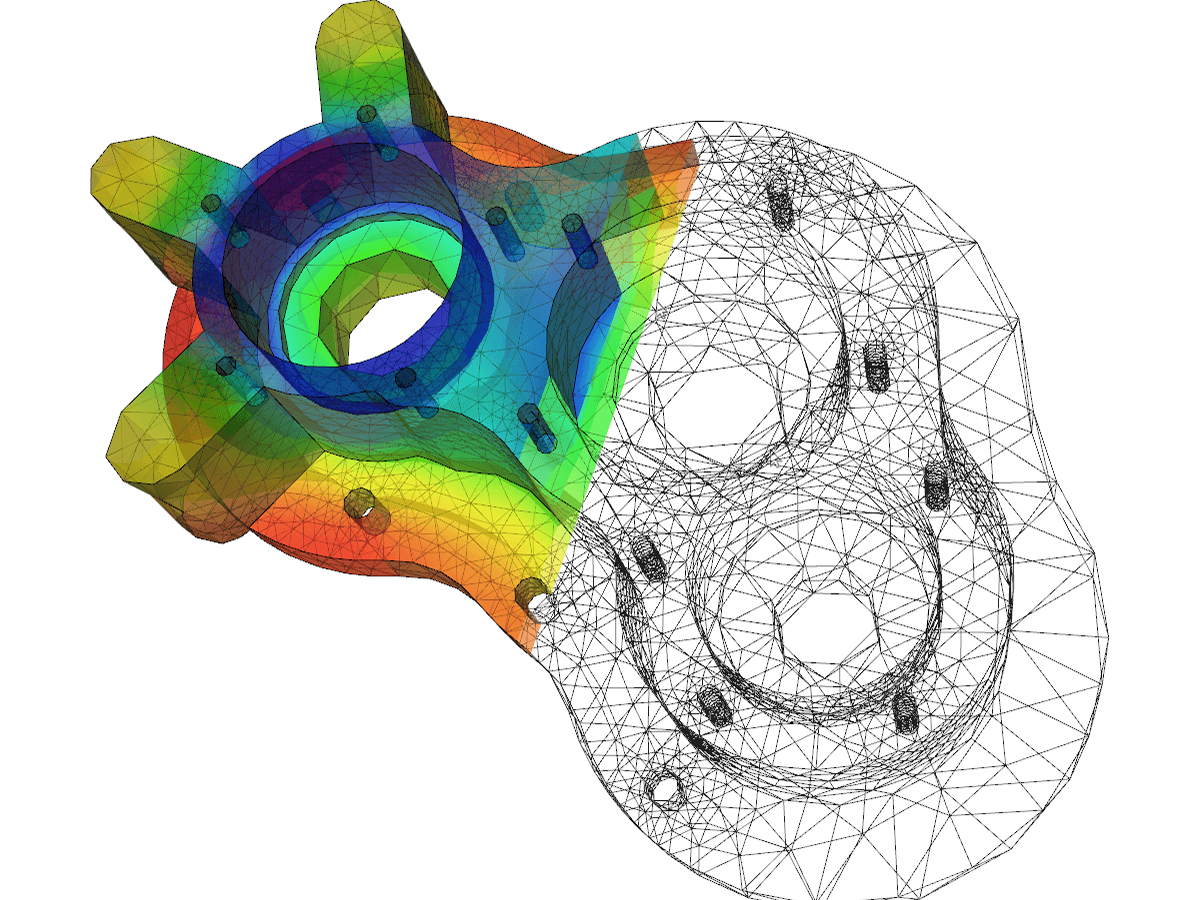

For my first rotation, I was a Manufacturing Engineer I. I started supporting the Process Validation for the RENZAN Carotid Stent, which I would later lead the validation efforts. In 4 months of my rotation, there was a business need for an engineer to design a new Membrane Attachment System for MicroVention's vascular occluding product, the Azur Vascular Plug. I handed off the validation to another engineer and for my remaining 4 months of my rotation, I lead the design, iterative development, testing, and implementation of the Azur Vascular Plug Membrane Attachment System. More details about my Manufacturing Engineering experience is detailed below:

• Led and supervised Process Validation efforts for the RENZAN Peripheral Vascular Stent.

• Developed new equipment from design to customer delivery and composed a modified manufacturing procedure for the AZUR Vascular Plug [AVP].

• Led and performed Statistical Analyses (DOE, ANOVA, IMR, etc.) to evaluate and guide design improvements. Extensive use of CAD Mechanical Design and Finite Element Analysis/Stress Analysis.

• Developed and executed a statistically driven R&D (JRD) study to understand the yielding characteristics of all product spooled Nitinol wires to justify in house spooling.

• Documentation Experience: IQOQ, TM, DT/TD, ES, MP, PPQP/PPQR, SMVP, QPL. Document Management through PTC Creo, Windchill.

• Developed new equipment from design to customer delivery and composed a modified manufacturing procedure for the AZUR Vascular Plug [AVP].

• Led and performed Statistical Analyses (DOE, ANOVA, IMR, etc.) to evaluate and guide design improvements. Extensive use of CAD Mechanical Design and Finite Element Analysis/Stress Analysis.

• Developed and executed a statistically driven R&D (JRD) study to understand the yielding characteristics of all product spooled Nitinol wires to justify in house spooling.

• Documentation Experience: IQOQ, TM, DT/TD, ES, MP, PPQP/PPQR, SMVP, QPL. Document Management through PTC Creo, Windchill.

Image Credit (3)

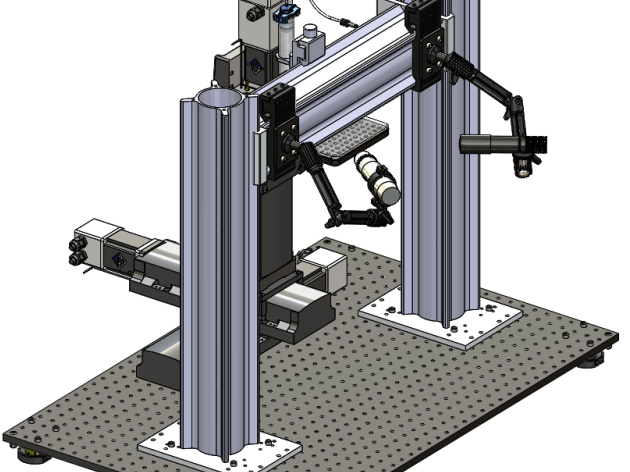

My Second Role: Engineer I - Equipment Design Engineering

March 2021 - November 2021

For my second rotation I was an Equipment Engineer I. I supported various projects related specifically to equipment development, ranging from design conception and prototyping to validation and implementation. More details about my Equipment Design Engineering experience is detailed below:

• Lead mechanical and software redesigns for various equipment projects simultaneously, supporting both California and Costa Rica Manufacturing lines from project conception to customer delivery. Extensive CAD Design.

• Created and executed SMVP, SSP, STP, STR, and SRA software protocols for Software Validation.

• Created Technical Drawing package and supported design of Automated Guidewire Transfer System (automated robotic arm system, 3000+ component assembly).

• Drafted and coordinated Quality Plans (QPL) for Equipment Qualifications (IQOQ).

• Supported machining, 3D printing, and PLC electrical wiring of manufacturing equipment.

• Manage CAD Documentation through PTC Creo/Windchill environment.

• Created and executed SMVP, SSP, STP, STR, and SRA software protocols for Software Validation.

• Created Technical Drawing package and supported design of Automated Guidewire Transfer System (automated robotic arm system, 3000+ component assembly).

• Drafted and coordinated Quality Plans (QPL) for Equipment Qualifications (IQOQ).

• Supported machining, 3D printing, and PLC electrical wiring of manufacturing equipment.

• Manage CAD Documentation through PTC Creo/Windchill environment.

Image Credit (4)

My Third Role: Engineer I - Business Analytics

November 2021 - March 2022

For my last rotation I worked as an Engineer I in the Business Analytics team. I developed marketing models and dashboards for executive guidance as well as supported non-technical tasks such as the FRED X merchandise launch. More details about by Business Analytics experience is detailed below:

• Created a Marketing Dashboard for CASPER Carotid Stent, showing ASP, Revenue, Units Sold, and other KPIs broken down regionally.

• Performed a Competitive Pricing ASP and Market Share Analysis for all Access and Coils products against competitors.

• Supported competitor and internal product comparison.

• Supported merchandise distribution for FRED X product launch.

• Performed a Competitive Pricing ASP and Market Share Analysis for all Access and Coils products against competitors.

• Supported competitor and internal product comparison.

• Supported merchandise distribution for FRED X product launch.

Image Credit (5)

MicroVention Terumo

MicroVention-Terumo is a neuroendovascular medical device company founded in 1997. The company was acquired in 2006 by Terumo, a Japanese based medical device company (1)

The company strives to provide minimally invasive catheter delivered implants to treat various neurological disorders, ranging from Aneurysm Therapy, to Neurological Malformations. To treat these conditions, MicroVention has developed an array of technologies, including but not limited to Microcatheters, guidewires, stents, hydrocoils, and balloon catheters.

More information about MicroVention-Terumo can be found with the button below.

Image Credit (6)

References

(1) “Microvention-Terumo: Culture | Linkedin.” LinkedIn, MicroVention-Terumo, https://www.linkedin.com/company/microvention/life/ur.

(2) Microvention, MicroVention-Terumo, 14 July 2016, https://www.microvention.com/news/orange-country-business-journal-article-on-microvention.

(3) “About Us.” Microvention-Terumo, https://www.microvention.com/about-us.

(4) Cinde. “Homeward Bound: Costa Rica Responds to Nearshoring Trends.” Investment Monitor, 3 Mar. 2022, https://www.investmentmonitor.ai/costa-rica/homeward-bound-how-costa-rica-is-responding-to-nearshoring-trends.

(5) “What Is Business Analytics?” Oracle, https://www.oracle.com/business-analytics/what-is-business-analytics/.

(6) MicroVention-Terumo, Inc. “Microvention-Terumo Announces New Leadership.” MicroVention-Terumo Announces New Leadership, Cision, 22 Sept. 2020, https://www.prnewswire.com/news-releases/microvention-terumo-announces-new-leadership-301135179.html.

(7) Carreon, Ed. “Los Angeles Commercial Event Photography.” Commercial Photography - Microvention | Ed Carreon Photography, https://www.carreonphotography.com/Microvention.html.